How can you ensure that a new vendor is the right one? You need to evaluate how a vendor is likely to perform, which you can do with this ten-step vendor management checklist. Investigate how the vendor rates on each of these 10 important points, then use that evaluation to determine whether you want to work with that vendor. This vendor management checklist will help you avoid costly mistakes from working with vendors that don’t or can’t deliver on your organization’s needs.

Key Takeaways

More than a third of companies today work with over 1,000 different vendors . Every new company you add to your supplier list needs thorough vetting to ensure they meet your company’s needs.

Smooth-talking salespeople or lower-than-normal pricing may entice you when looking for a new supplier. Only after you sign the contract and wait for your deliverables do you discover that the vendor can’t deliver on its promises—shipments are late, pricing is higher than promised, or the quality isn’t there.

Avoid these costly disappointments by thoroughly investigating all new vendors before you commit. When you find out all you can about a supplier, you can feel comfortable choosing one that not only offers a fair price but also communicates well, fits within your company culture, is reliable, and will be around for the long haul. Ultimately, all of these things matter—which is why you need to check them out.

SOURCE: Online PM Courses via YouTube

Evaluating a vendor takes time and effort. You can do some of it online or on the phone, but you may also need to visit the vendor to get a first-hand look at who you’re dealing with.

To evaluate a vendor, you’ll need to:

How the supplier answers those questions—and responds to your investigation—will determine whether you want to begin working with that vendor.

You want a supplier that delivers on all promises and promptly responds to your issues. When you scrupulously vet a supplier, you’ll be more confident that you’re making the right choice.

To complete an exhaustive evaluation of any new supplier, follow this ten-step vendor management checklist. Work through the checklist item by item to know whether you want to work with this vendor.

Begin the vendor evaluation process by collecting relevant contact information for the vendor. This data should include:

Determine who the key point people are in the organization and know who to contact when you need something done without having to work through a lot of red tape.

Capacity should be a simple one. Does the vendor have the capacity to deliver what you order? What about if your orders increase over time? Dealing with a small supplier might have some advantages, especially in terms of communication and commitment, but it’s a bad fit if they can’t handle your business. It’s important to understand their service level agreements (SLAs) both now and over time as the relationship expands.

Data security is a huge issue, especially if vendors have access to some or all of your company’s data systems. When you link systems with another company, your data is only as secure as the weakest link—which could be the vendor. According to the State of Third Party Risk Management report, 31% of vendors are data security risks. Check out a supplier’s data security program before interacting with them.

SOURCE: https://www.venminder.com/

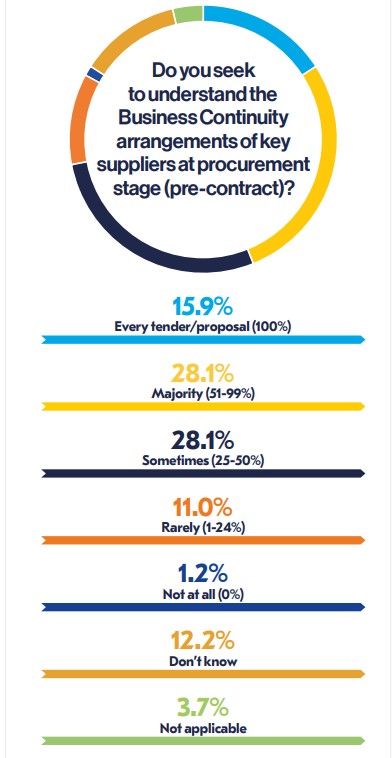

Consistent service is a necessity, which is why it’s surprising that just 16% of companies investigate the business continuity arrangements of their key suppliers. Business continuity ensures consistent product quality and service no matter what issues might develop. Don’t deal with a vendor that sacrifices quality to meet schedules or misses schedules to meet your quality standards. Rely on one that delivers on all promises consistently.

How much control does a vendor have over its processes? A vendor that outsources multiple processes to third parties might lack the control you need to deliver your orders on time. When a supplier depends too much on other companies, it can’t guarantee its promises to you.

If product quality is important to you, and it undoubtedly is, you need a supplier that consistently delivers a product that meets your quality standards. Evaluate their product beforehand to ensure that it’s up to spec. Make sure you understand their quality control or quality assurance (QA) process and standards.

Not enough companies consider vendor compatibility. Work with vendors that are compatible with your company culture. If you’re a straight-up ethical organization that follows all the rules and takes care of your employees, you won’t like working with a company that cuts corners and treats employees like disposable resources. Find companies that share the integrity and key values of your company, then work closely with them to nurture a mutually beneficial relationship.

Likewise, you want a vendor that is easy to communicate with. You need to know who to contact in any given situation and be assured that you will be able to talk with them and receive a timely response. Working with offshore vendors could be challenging, where language and time-zone barriers can make even simple communication difficult. Whether you communicate via email, text message, or phone call, ensure that your two companies are on the same communications wavelength. It may also make sense to schedule a regular communication cadence or check-in depending on the relationship.

You don’t want to start dealing with a supplier today and find out they’re going out of business tomorrow. You also don’t want to work with a vendor that doesn’t have the financial resources to produce, source, and deliver your orders as you request. Investigate the company’s financial records to ensure they have a clean bill of financial health.

Finally, you have to consider pricing . Cost might be the least important factor in choosing a supplier, but it’s still important. You may be willing to pay a little more to get a reliable, high-quality supplier, but you shouldn’t have to pay too much more. Another key here is to document how pricing may change over time and with different volumes, both higher and lower. Finally, are there discounts or penalties associated with the vendor’s performance and commitment to deadlines?

When you’ve worked through the vendor management checklist, thoroughly evaluated a given vendor, and given that vendor a thumbs-up, it’s time to write up the contract. Contract Logix’s contract management software helps you automate and manage the entire contract and vendor management process, from inception to execution and beyond. It’s the best way to maintain a strong relationship with all your vendors and get a better grasp on your contract management.

Contact Contract Logix to learn more about vendor management and contract management.

Looking for more articles about Contract Management? Check out our previous article “The 1-2-3 Guide to Digital or Electronic Contract Signing“.